Acoustic control of airborne and structure-borne sound in high-density residential areas are a significant concern for contractors. TMS Silent Clips - A237R are well suited for solving this problem and can increase STC points by a minimum of 7 points through simply replacing standard direct fixing clips with Silent Clips.

A237R clips are used in the process to create a "floating wall or ceiling" where walls or ceilings are decoupled to create resiliency and break sound waves. The unique sound cell design of the A237R clips guards against structure-borne vibrations transferring into the body of the clip and leaving just a small percentage of contact surface area between the clip and the structure or substrate that it is fastened to. This aids in absorbing and breaking up airborne sound at its transfer point. In addition, its patented thermoplastic rubber outperforms standard rubber with its unique natural absorbing characteristics.

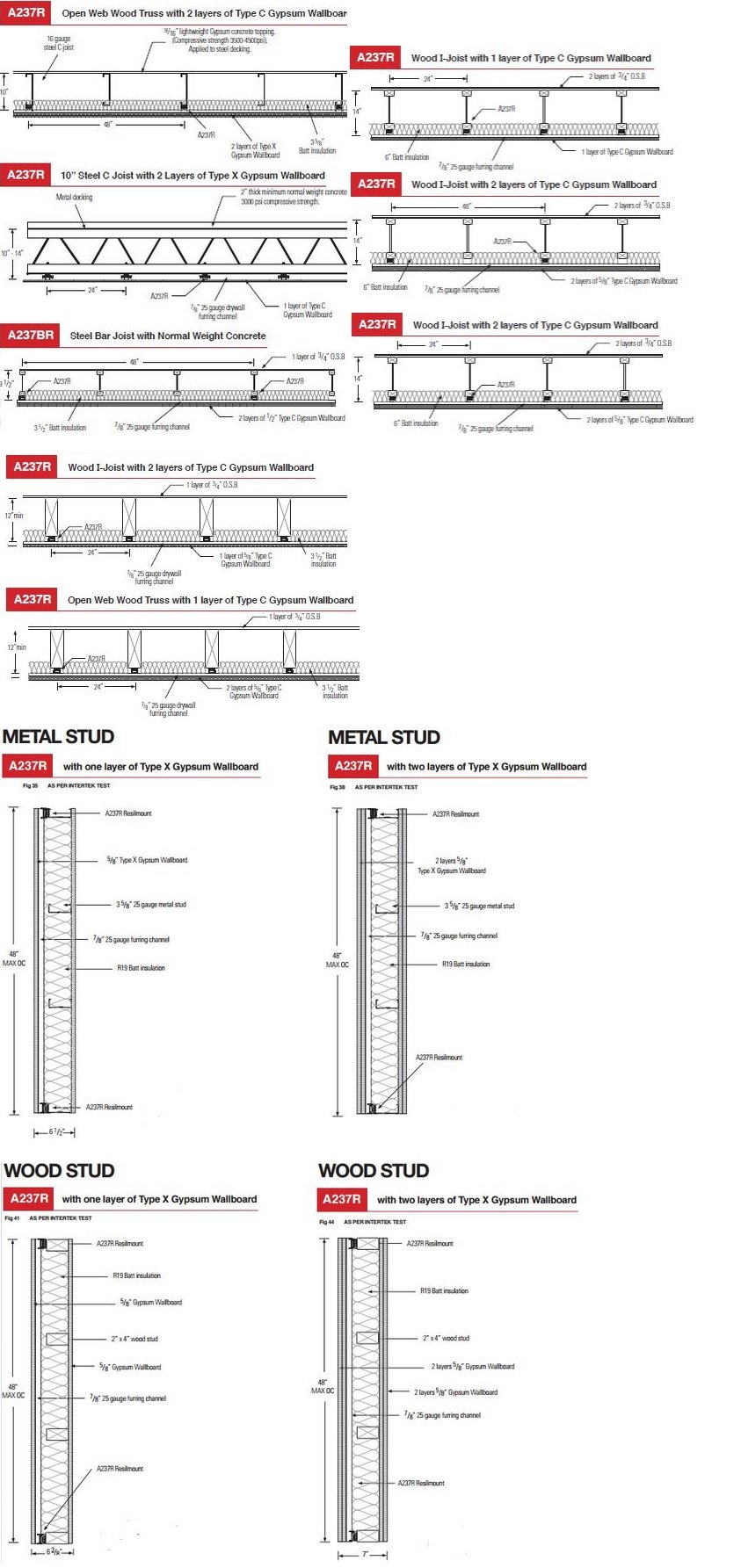

Clips are designed with a 1.4" inch opening to be applied to any substrate using screws or masonry anchors. A237R clips are designed to hold a furring channel with one or more layers of gypsum wallboard attached. The load capacity of the clips depends on the gauge of the hat channel used. They can be used in both wood and steel applications.

It is UL Classified for use in a 1 hour assembly with 1 layer of 5/8" drywall, making it well suited for use in apartments, condominiums and other applications in sound control. It can be used to soundproof ceilings and walls in many fire-rated acoustic applications. (see our Product Data tab for Acoustic and Fire-Rating test results.)

Features:

- Engineered thermoplastic rubber with outstanding sound absorbing characteristics

- Simple design; adaptable to hundreds of applications

- Consistent and reliable quality; manufactured under ISO9001 quality control system

- Cost effective solution to isolate airborne noise

- Equipped with pre attached fire washer

- Unique 2 step locking system allows for Furring Channel to be locked in place

- A237R clips can be used to suit 7/8" and 1 1/2" furring channels

- A237R clips are provided with a 1/4" hole for a variety of fasteners

- 1 hour and 2 hour fire-tested

Applications:

- Multi-family housing

- Mixed use commercial buildings

- Studios

- Home Theater

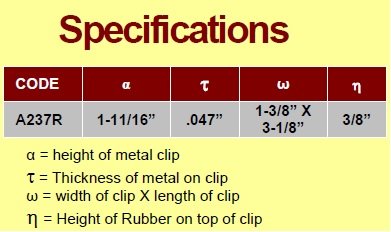

A237R Clip Specifications:

- Width: 1.375"

- Height: 3.25"

- Depth: 1.125"

- Weight: 0.25 Lbs.

- Max spacing between clips: 48" OC

- Max load: 36 Lbs.

Hat Channel Specifications:

- Height: .875"

- Width: 2.5"

- Length: Typically 12'

- Splicing: 6" min. overlap, secure laps with 2 steel framing screws or wire.

How Many To Order:

Clips can be spaced up to 48" apart with spacing of up to 24" between channels. When using this spacing, divide the square footage of the area to be treated by 5. That will give a rough estimate of the amount of clips needed. In most cases you will need to compensate for being within 6" to walls/ceilings so we have found that calculating the square footage by 23% should get you close to the amount of clips needed. See Installation Tab above for layout diagram.

For detailed usage see our How To Soundproof Article.

Need help planning your soundproofing project? You can always call our office at 845-388-1200 with any installation questions that arise. Feel confident when placing your order with Trademark Soundproofing, as we are always here to assist you with installation advice and tips. We are the only soundproofing company that is constantly installing the products we sell, so we have the answers!