1) Charles B, Architect: I need to provide STC 52 between apartments using 2x6 stud wall.

Trademark Soundproofing Reply:

Hi Charles, Resilient Sound Clips and Channels will get you into the 50's when used in conjunction with insulation. See our Whisper Clips here. Keep in mind that if you have an open air space above the wall you would have to treat the ceiling too. Thank You.

2) Charles B, Architect: I need to show proof of STC rating to the Building Department and the wall has to have a one hour rating.

Trademark Soundproofing Reply:

Hi Charles, See the Data sheet here showing the Orefield Lab test results. Please email us if you would like a copy of the actual test. We'll be glad to send it over.

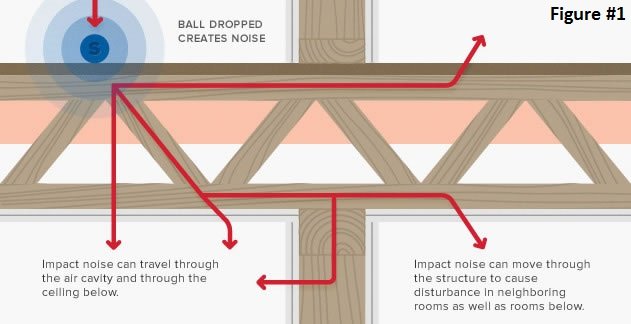

3) Tim: I am working on finishing a basement are and was just going to put drywall on the ceiling. Space is a huge issue, basically lack of it. I was looking through your products and found the Mass Loaded Vinyl. I can not put it down under the floor above, however can put it up before I put the ceiling up in the basement. I do not expect complete quiet. However I am thinking it will reduce things like hearing the cat run around upstairs. Thoughts? Thanks, Tim

Trademark Soundproofing Reply: Hi Tim,

MLV is a good sound control material especially when your tight on space. For impact sound on the floor above as in your scenario you really need to decouple the ceiling and/or treat the floor itself. If that is not possible than this would add some sound control. Thank You,

4) Ben B: Hi, I'm refinishing my basement and the ceiling is completely exposed and I would like to try to reduce the sound from footsteps above and noise below. I've been thinking about putting R19 in the joist bays, but i've also heard/read that another problem is the drywall attached directly to the joists also transmits noise. So will your Joist Gasket Tape reduce that considerably? If so, my next question is about gluing the drywall to the ceiling in addition to the screws to prevent sagging. If there is your tape there, it seems the glue would be only as strong as your adhesive, and not needed. What do you think? Thanks Ben

Trademark Soundproofing Reply: The Joist Gasket would help somewhat but not 'considerably'. Real decoupling requires the use of Resilient Sound Clips and Channel.

You are correct that the adhesive glue will not add more than the adhesion of the tape.

5) Sharmaine C: He,

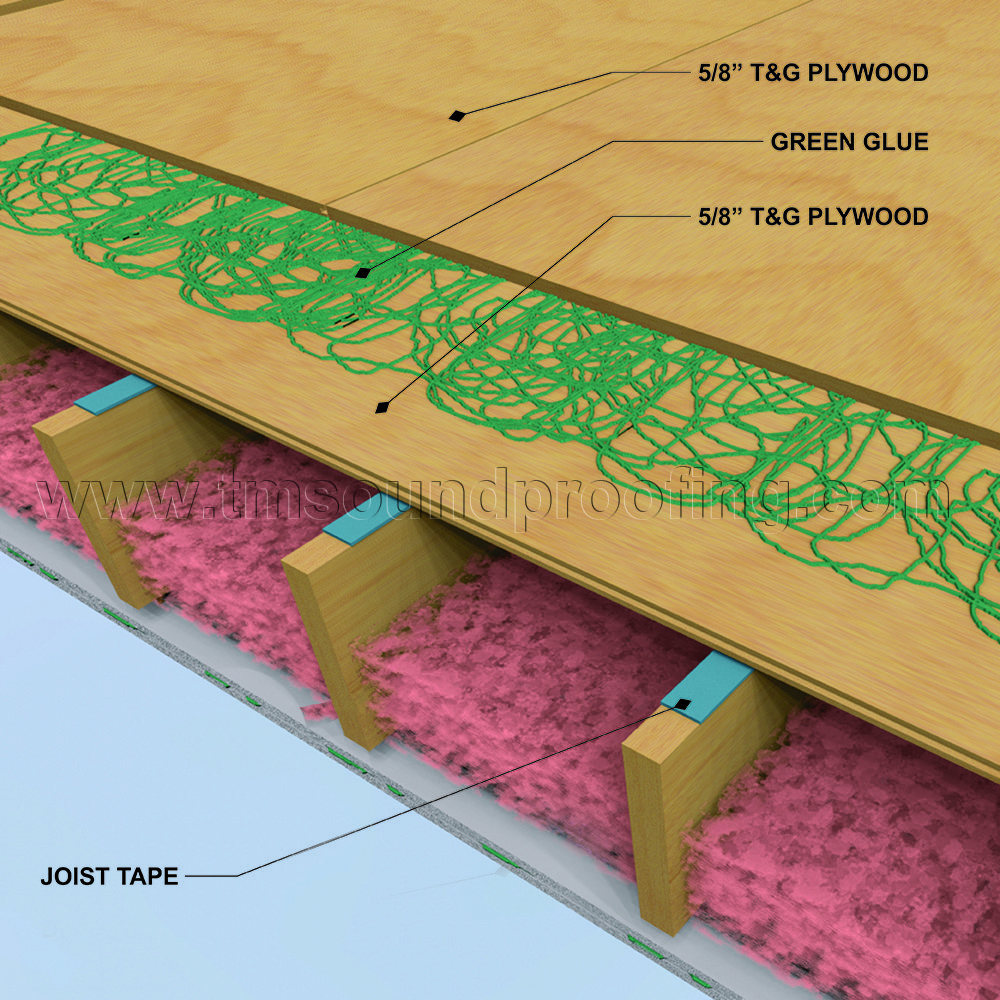

We love Green Glue and need instructions how to install it with tile. The tile guys will use a mortar bed, not cement board. Also, is there a way to use GG to help deaden the sound of a 2nd floor toilet from the room below? The sound of water in the toilet is quite loud from below. Thanks for your advice.

Sharmaine

Trademark Soundproofing Reply: Hi Sharmaine,

Thank You. The only way to do that would be to put down a 2nd layer of plywood with the GG in between and then do the mud job on top of the 2nd layer.

For the toilet you would need to a 2nd layer of drywall to your ceiling and the walls with GG in between.

Thank You,

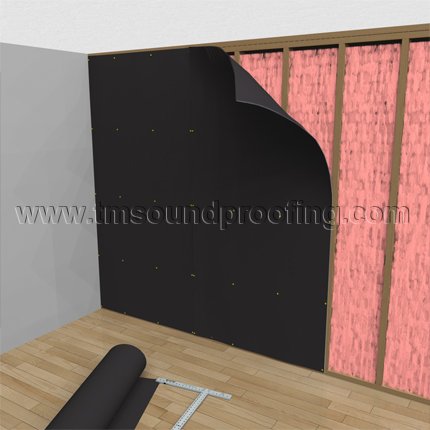

6) paul: I am trying to soundproof a basement woodshop. I have a row house with brick party walls between neighbors. I read that decoupling and adding mass will help. Is the viscoelastic green glue recommended or is that more effective with low frequency noise? Your help is appreciated.

Trademark Soundproofing Reply: Hi Paul, Green Glue Viscoelastic Damping Compound is very effective on all frequencies including low frequencies. It can be used in conjunction of Mass and decoupling. You will automatically have more mass when you add a 2nd layer of drywall however decoupling will require that you remove the existing wall and start from the studs.

7) Bill: When using resilient clips and channel, the detail is to caulk between the walls and the ceiling. Can you then tape and Sheetrock the joint or does tha defeat the sound damping properties ?

Trademark Soundproofing Reply: Hi Bill, Yes, tape and joint compound will not compromise on the sound proofing done.

8) Vicki: Planning a 2nd story addition over existing master bed/bath.

It MUST be completely separate and quiet. Now have a flat roof with zig zag trusses,4' rigid foam and IB membrane roofing. Will adding another separate flooring system over this, using the subfloor green glue/soundproofing mat and tape be enough? What about homeasote? Install under the subfloor?

Trademark Soundproofing Reply:

Hi Vicki. Adding a 2nd flooring system would help. Best practice would be to apply joist gasket tape to the top of the new floor joists then 2 layers of half inch subfloor with the Green Glue Damping Compound between them. Fiberglass insulation between joists. We would also highly recommend that you decouple between the floors. This can be done by either redoing the existing ceiling with Resilient Sound Clips and channels or be installing the new floor joists onto rubber joist isolators. Thank You.

9) Robert T: Love the website. New two story light commercial construction question. Plan to follow the recommendation of gasket tape, subfloor, green glue, 2nd subfloor and finished floor with underpayment. For aesthetic reasons would like to NOT have an enclosed ceiling below, that is, I prefer to expose the underbelly of thre floor system and apply gapped wood planks (deco treatment) at bottom of the floor truss. Have considered coating the underneath of subfloor and truss with open cell foam before applying the wood slats. So questions are these - will the OC foam be as effective as sound batts, and can I survive the lack of drywalled ceiling, or will the loss be too great?

Trademark Soundproofing Reply:

Hi Robert, Thank You. Perfect way to do the floor. As a soundproofing company we do notrecommend an open ceiling plan. As you require some kind of decoupling and space between the floor and ceiling. As far as insulation goes fiberglass is better than spray foam for sound. If you have the room on the floor you can construct a decoupled floor using rubber joist isolators fill with insulation and then do the double plywood and Green Glue.

10) Robert: Thanks much for the reply, and my apologies for the delayed response. So what I hear is a) Yes, remain with the intentions on the 2nd story flooring; b) No, open cell foam won't mitigate sound as well as sound batts; c) No, you wouldn't recommend leaving the ceiling open on the lower side (with deco wood slats); and d) install rubber joist isolaters beneath the first layer of 2nd story plywood if possible.

Few more questions for you ?

1) Do I presume that rubber joist isolaters would negate the need for the rubber gasket tape?

2) Would the addition of the isolaters make you feel better about the possibility of the exposed floor system on the underneath side?

3) In regards to the ceilings at the underneath side (assuming it's not left exposed), would the addition of suspended acoustic panels negate the need to sheetrock the underneath side of the floor system?

Thanks again in advance.

Robert

Trademark Soundproofing Reply: Hi Robert 1) That is correct although the tape would still help to eliminate squeaking between the sub floor and floor joists.. 2) Somewhat better. 3)Not by a lot as acoustic panels are meant to control the acoustics in the room and not block sound from passing through.

11) Laverne: Hello, I have a separate suite in my basement and I want to soundproof the basement ceiling from sounds coming from the main floor above including voices, dog barking, and footsteps. I am going to follow the steps you mentioned however because of a tight budget, I only want to do the ceiling above the bedroom and living area. The bedroom and living room is separated by a hallway. I am wondering if soundproofing will be pointless if I don't do the hallway too? What do you think?

Trademark Soundproofing Reply: Hi Laverne. It would depend in which direction the ceiling joists run. If you are lowering the ceiling using clips and channels it is less of an issue.

12) Nazar: Hi, I want to soundproof a room from noise of diesel generators. The sound level of the generators is not less than 110dBA. This room is being used as control room for these generators. What techniques and materials should be used for the purpose?

Trademark Soundproofing Reply: Hi Nazar, We need more info on the construction of the walls and ceilings there. The general rules are still the same. Decouple walls and ceilings, add mass and damping.

13) Marcel: I live in a four story condo complex. We can hear the people above us and it becomes quite noisy even if they are walking around. Is there something we can do to eliminate the sound transfer. Our ceiling is a finished textured ceiling

14) Tom T: Hello. This is a question about existing walls. Would there be good soundproofing by just adding another layer of sheetrock to the existing wall using green glue?

Thank you

Trademark Soundproofing Reply: There would be if there is already insulation in the cavity behind the first wall.

15) Tom T: Hello. I have a question about the ceiling. All along the eves there are many, many holes I guess for venting. Would it be possible to cover the eves with joint compound or MLV to eliminate the traffic noise with out doing any damage to the house?

Thank you

Trademark Soundproofing Reply: You would have to check with your insulation contractor.

16) joshua z: If 2 layers of subfloor are used with green glue between them, is screwing the second layer to the joists necessary? Won't the screws transfer vibration?

Trademark Soundproofing Reply: Yes it is neccessary. Screws transfer vibration when you are trying to decouple and the screw short circuits the decoupling. With Green Glue you are damping the layer and the screws do not effect the damping .

17) Devon S: I am planning on installing standard lighting fixtures (not recessed). What should I use to soundproof the holes in the drywall? Thanks

18) Mike: Hello,

I'm building a drum studio with double walls, the draftman who has drawn up plans for this has said that the building needs to have a sheet of 2.4x1.2m plywood or gib inserted on each of the 4 corners of the building inside the wall cavity to meet building code and brace the building so it will stand up (because of the exterior cladding that I am using), my question is will this compromise the double wall system? Thanks for your time.

Trademark Soundproofing Reply: Hi Mike. We would need more details to fully understand the construction. However if the plywood is attached to on wall only than you will not be compromising the double wall system.

19) Shane: After my ceiling is sound proofed with insulation and resilient clips. How do I fill in the gap between the ceiling and the wall. If I use acoustical caulk, can I still use joint tape and joint compound to over the acoustical caulk?

Trademark Soundproofing Reply: Yes. No problem there. Just smooth the caulk down(with your finger) and then spackle and tape right over it.

20) Janet: Want to soundproof my basement ceiling from noise above, ie footsteps tv etc

Height is an issue so if I put 5/8 drywall between joists with gg, insulation then drywall would I get enough sound dampening. Also wondered if Ithe was worth putting gg or gg sealant along joists before putting up last sheet of drywall. Ideally I would decouple with clips but really don't have the height. Thanks

Trademark Soundproofing Reply:

Hi Janet. No point in putting GG on the joists before installing the drywall. For height restrictions we have been getting excellent results by using insulation 2 layers of drywall with Green Glue onto the joists and the premium carpet underlayment with carpet on the upstairs floor.

21) Janet: Thanks for your response.

So just to clarify... sound insulation first ..2 layers of drywall with gg in between and attach directly to the joists.

No need to put gg & drywall on floor between joists and no need to put gg on the joists.

Thank you

Trademark Soundproofing Reply:

Correct. You can put drywall with GG in between the joists to the underside of the floor if you will not be using clips and channel. It will help somewhat, much better if you can do clips and channel. No point inputting Green Glue onto the face of the joists. If anything use the joist gasket tape. These are mainly used for the top of floor joists however we have builders that use them on walls and ceilings too and say that it helps.

22) Janet: Thanks for all your help.

One more question, would it be okay to use 1/2' for the second layer or do I need to use 5/8's.

Thanks in advance I really appreciate the advice.

Trademark Soundproofing Reply: Half inch is fine.

23) Brian: I am working on a project in an existing commercial office building and there is existing carpet on the 1st floor slab on grade and on the existing 2nd floor slab on deck. The 2nd floor is supported by steel beams and metal open web floor joists. The documents called for the existing carpet to remain in most areas. The wall details call for sealant to be provided at the bottom of the drywall for acoustical reasons. The drawings do not specifically indicate that the existing carpet needs to be removed prior to the wall being installed. Therefore, the Architect is saying that the metal track cannot be installed over the existing carpet. Is there any details that you know of that provided me with support that the carpet should remain as it provide more acoustical value that removing it and installing the sealant? Please advise.

Trademark Soundproofing Reply:

Hi Brian. I don't know of any detail and technically if that is what the plans call for, the Architect has a good point. Carpet under the track is not a proper 'acoustical seal' vs acoustical caulk which is.

24) jim: how to finish the outlets, switches, and door jam. if the soundproof wall is 2' - 3' out from the wall studs, that means the switch and outlet boxes will be recessed in the new wall. the door will be aligned with the studs of the original wall. how do you make the boxes and door flush / finished with the new wall surface? i am unable to find details on this anywhere.

thanks, will you email me or do i have to look here for answer?

Trademark Soundproofing Reply: Hi Jim. You can bring outlets boxes forward or get longer screws for the plate.

For the door you can get what is called an 'extension jamb'.

25) Brad B: Your website is great. I am a Roofing Contractor and used to be a carpenter/finish carpenter, so my knowledge on 'Correct' Soundprroofing just began a few months ago as i am finishing my own basement. So I have almost all my framing complete but in my media room I have many different ways to go on Insulation/Rc clips/hat channel/MLV/carpet pad, etc. etc. Forgive me if I don't use your exact products, but some of the prices are out of my range as I am over budget as I encountered an unexpected issue that had to be resolved (mold on above grade interior foundation wall!). So I've had many of my guys come over with their opinions and have formed my own, but after reading YOUR site, everyone else's opinions are out the window. My main concern is the open 16' o.c. Ceiling joists that i want to be total (or close) to sound proof. I was thinking of using a roofing product (and I'm really glad i found the words EPDM on your site. I have mentioned using this to many people with everyone looking at me like I didn't know what i was talking about...what if i ROXUL insulated first, spread and stapled the EPDM sheet taunt (i can get custom cut sizes at my roofing supplier) on the bottom of the ceiling joists for MASS, then used wood 2x3s tacked in a grid system on top of that (for another air space), then correctly spaced RSIC-1 clips, then double leg hat channel, then 1 layer 5/8 drywall...?? What are your thoughts?

1. Also can i 'wrap' the whole room in EPDM sheet ?

2. Also there is 45 mil, 60 mil, and 90 mil thicknesses, what would you suggest?

3. I also Fire Foamed all around the electrical boxes, that ok?

4. Also was wondering if I can put the EPDM on the floor? It is an impermeable rubber-roid material, then carpet pad?

5. Also I already have my hat channel i found at a local big material provider. It measures 2 5/8. An 1/8 bigger than the max acceptance, im assuming this is ok...?

6. Also what are your thoughts on 'closed cell' foam? I noticed a post above about open cell and was not recommended. I have to do this on my above grade foundation wall to prevent any future mold problems, but is just going on 1 of 4 walls of the room.

Sorry for the long winded message.

Trademark Soundproofing Reply:

Hi Brad. Thank you and your forgiven  . I am not familiar with the use of EPDM as it applies to soundproofing. In general it would depend on the weight. I would suggest that at least for the ceiling you should consider swapping out the EPDM for mass loaded vinyl. I would also simplfy your ceiling construction by eliminating the 2x3 grid system which will not add much as you will get the extra air space and proper decoupling with the RSIC-1 clips and hat channels.

. I am not familiar with the use of EPDM as it applies to soundproofing. In general it would depend on the weight. I would suggest that at least for the ceiling you should consider swapping out the EPDM for mass loaded vinyl. I would also simplfy your ceiling construction by eliminating the 2x3 grid system which will not add much as you will get the extra air space and proper decoupling with the RSIC-1 clips and hat channels.

1. You can do that again I don't know the sound ratings for this product. You may also want to check with an insulation contracrtor to make sure there are no moisture issues.

2. I would say that the thicker the better as this would be working by supplying mass.

3. That is fine.

4. See number 1 above.

5. If it fits into the clip than it is fine you may have some extra work getting it in there.

6. We do not recommend closed cell foam for sound proofing as it is extremely rigid. You want insulation to 'absorb' sound waves.

26) Brad b: Hi again

3 questions if u could answer quickly id very much appreciate as my drywallewrs are coming in 3 days .

1. I ran out of time to order RSIC clips, what if i used a styrofoam padding ( 4' wide) , then folded it in half and slap stapled it to my walls and ceilings. It is another building material used in between the top of the foundation and the first 2x4 sill plate (designed to stop air infiltration and bugs. It is similar to gasket tape, but no sticky side. My thoughts were it would give a 'padding ' between studs and drywall . Especially when folded in half gives a pretty good pad, maybe 1/2', would this help at all, or am I totally gasping for ideas at this point..

2 . difference between whisper clips and rsic clips. Is it locations ?

3. Im going to do the strips of drywall between my ceiling joists to help above sound , do i use gg dampening tube or gg acounstical sealant. The acoustical sealant is only one i can get near me at local home store...

4. Do u expedite shipping ?? Lol

Thanks for timely response if possible, my next room im allowing a bigger budget and more planning

Trademark Soundproofing Reply:

Hi Brad. The procedure that you mention will not give you anywhere close to the sound blocking vs using the RSIC-1 clips as you are not properly decoupling. There are slight differences between the 2 clips as far as UL ratings and method of installation. You would use the Green Glue damping compound, not the sealant. Why do you think you ran out of time? We have all the clips in stock and can ship them out same day and we offer the option of overnight shipping. Give us a call 845-388-1200.

27) Fernando L: Hi,

I'm thinking about using Green Glue when we install the new floor in a currently gutted 90 year old house. Currently it has old plank subfloor. Can I apply Green Glue between plank subfloor and plywood?

If that is not recommended, what would be the next thing least expensive way to do it? I'm thinking Green Glue between 2 OSB layers on top of the plank subfloor? Please let me know what you think.

Many thanks!

Fernando

P.s. the information available on your website is awesome!

Trademark Soundproofing Reply: Hi Fernando. As long as there are no large gaps in the planks and it is generally smooth you can do it. Otherwise use 2 layers.

Thank you and we appreciate your feedback!

28) Billy M: I am building a sound proof recording studio in the out building/Oversize shed on my property. it is 14 x 14. the floor is currently hardwood in need of a new stain... I'll be sad to rip it up but I need it to be as sound proof as possible so the neighbors don't call the cops. the building has a cement foundation, your website shows in great detail how to sound proof a floor that is to a second floor.... what about ground level ? I keep reading about U-Boats ? Suggestions ?

Trademark Soundproofing Reply: You should not have that much of an issue if it is a slab to ground floor as long as you treat the walls and ceiling properly. If you want you can add a layer of plywood/OSB with Green Glue in between to the existing floor and then finish the floor.

29) Rob : Looking at the cost of green glue vs. a Quietrock for a renovation that is gutted down to studs (looking at your new construction guidelines for the most part) Green glue needs 2 tubes/4x8 and 2 1/2' 4x8's

2 4x8 drywall (at $11 ea.) is $22 with and 2 tubes green glue at $35.

Green glue is $57 per 4x8 total.

Quietrock is $50 per 4x8 total.

-Is the Quietrock a cheaper option with sound STC ratings pretty close to green glue?

-could still use the low profile resilient clip and hat channel (ceiling height is a concern)? Quietrock 5/8 ' vs. 1' of Green glue also?

Thanks

Trademark Soundproofing Reply: Hi Rob,

The cost of the GG will go down when buying multiple cases. Additionally the ten percent or more waste is of plain drywall only and of the expensive pre damped drywall.

Thirdly you cannot get a 1 inch thick or even 5/8) pre damped drywall at that price. You are comparing a half inch thick which is 2 layers of 1/4'. Therefore the 1 inch layer you are constructing with Green Glue will be far superior.

Also when using your 2 layers you get to overlap the seams which eliminates sound leaking through the gaps.

Finally, when using Green Glue you are also knowing that you are using the correct amount of material needed per sheet .

Definitely use resilient sound clips and channel if possible, it will add a lot to the sound control performance of your ceiling.

30) Herman: Hi,

I am building out my office and we have two types of stud walls - metal frame and wood frame. There are many shared walls (office to office, office to conference room, office to bathroom, etc...). I am wondering if adding the insulation inside the metal frame walls and the whisperclips and green glue on the wood frame walls - both on single sheets of drywall would be sufficient for moderate office noise? There will be insulation above the floating ceiling.

Thanks for all your help on this site!

Trademark Soundproofing Reply:

Hi Herman. You should be treating the wood and metal frames in the same way. Insulation is a must for starters and adding Whisper Clips and Channels to one side of the wall is great. Green Glue can only be used between two layers of drywall in order to be effective. All this will not help if you have an open drop ceiling. See our video here on how to fix that. https://www.youtube.com/watch?v=gzdU5OiJMs4&t=1s

31) Rob: Thinking of doing most of my ground level ceiling.Looking to probably do one area fully with resilient channel and clips to reduce impact sound there. Then another room without resilient and work more to reduce airborne sound transfer, this will have high hats and needs to also be addressed. Ceiling height is a concern throughout.

Thanks

Trademark Soundproofing Reply:

Hi Rob, You can use low profile resilient sound clips if ceiling height is a concern. For the high hats. Consider using LED surface mounted ones that only use a standard electrical box which you can cover with a putty pad.

32) Dalia: Newly built home. Master bedroom is very close to neighbor's driveway/basketball hoop. We can hear them playing and cannot sleep. Very deep vibrations. Would soundproofing our room prevent this outdoor disturbance? We have a tray ceiling, windows in master, unfinished basement under us, and master bathroom separated by a wall and sliding door. Help!

Trademark Soundproofing Reply:

Hi Dalia. Of course it would help, that is what soundproofing is meant for. Problem is most people will not properly soundproof a newly constructed room which basically means redoing the entire room. You may want to start with your windows and see if that helps. See our Soundproof Window Panels.

33) Mark : Installing and engineered hardwood floor throughout my Coop, which has concrete between floors. We are planning to install a 3/4 inch plywood subfloor over 1x6 sleepers either glued or fastened to concrete floor. Loolking for recommendation of an underlayment and also would I add some type of insulation between sleepers and under the plywood? Thanks Mark

Trademark Soundproofing Reply:

Always good to add some insulation however you are limited here due to the height of the sleepers. Try to get a fluffy insulation rather than a stiff board. A rubber underlayment will help with the footfall noise.

34) Barry S: HI, I'm building a new single-story home in the coming year (2018). The floorplan includes a 16x23x10 home theater, 19x14x10 music room and two smaller rooms (drum booth, vocal booth). I'm interested in soundproofing all of these. I plan to use whisper clips and 2 layers of drywall for walls and ceiling. I'm most curious about my floors--they will be installed on a concrete slab, with wood flooring. Would a rubber isolation be sufficient, or should I consider dropping the floor 4' and installing a floating floor? Thanks--great web site and products.

Trademark Soundproofing Reply:

Hi Barry. The floor on the slab does not need major treatment. You can consider using a double layer of subfloor with Green Glue in between to create a damped floor. Thank you.

35) Ashley: Looking to have an entire length of our old brick row house soundproofed. The current wall appears to be double brick and plaster. There are a few small settlement cracks along the plaster wall ? things would would expect to find in a 120 year old home. Our neighbours recently completed a renovation and it has become quite clear that there are serious noise flanking issues. In addition to addressing the noise flanking, we?d like to achieve a minimum STC 50, it?s likely around 30 right now ? we can clearly hear full conversations... A stud of wall if out of the question as our staircase is on the same wall. Which would provide a better STC rating; option 1: mass loaded vinyl and Sheetrock or option 2: green glue and quiet rock or Sheetrock? Would you recommend leaving the plaster on the walls, repairing cracks and adding mass on top? Or removing plaster down to brick and adding mass from there? Hoping you might be able to advise. Thank you kindly in advance!

Trademark Soundproofing Reply: Option 2 would be better only if you will use 2 new layers of sheetrock with the Green Glue in between them. If you will only be using 1 layer of sheetrock than go with option 1. You can leave the plaster in place unless it will allow you to add insulation in the wall which is probably non existent now.

36) Joey R: Basement Ceiling, Rafters; 2 x 12's , 12' O.C., I only have 80' from floor to bottom of rafters. Planning to add dropped rafters ( @ 1/2' lower)between existing 2x12's to decouple new ceiling which will be double 5/8 drywall with Green Glue. Question is about insulating existing bays. Is it better to fill the bay completely or leave air space in the bay. Due to the fact that the bays are only 12' wide I will be cutting the batts to fit the width. My thoughts are that R-38 (12' tall) would better dampen the resonance of the 2x12's as opposed to something that is not as tall (R-13/19/30) for example. This will be a band practice room so I need to shoot for the highest STC rating possible with an emphasis on eliminating the lower frequencies ( 250 hz and below) to keep from rattling the China and Wine glasses off the shelves in the room above.

Trademark Soundproofing Reply: As long as the insulation is fluffy and not compressed you can fill the entire cavity.

37) J Nizich: Interesting and informative web site. My question is about stone tiling over a sound dampend wall. The wall is Safe & Sound, 5/8, Green Glue, 5/8. Wife loves the idea of tiling this as an accent wall and I was wondering if this will have a more soundproofing affect and result in a higher STC. Thanks

Trademark Soundproofing Reply: Thank you. We have no testing on that however it adds some more mass, so it should improve the STC slightly.

38) Mike R: I am building a new house, trying to acoustically separate a family room on the second floor from an adjacent bedroom on the second floor. I have the opportunity to frame the floor such that the floor joists for the bedroom and family room are both supported by a common beam between them, but the joists themselves would not be continuous from one room to the other. Is there anything I could do with the joist-to-beam connections on either or both sides to help mitigate vibration transmission through the beam?

Trademark Soundproofing Reply:

You can connect the floor joists to the beam using a resilient sound clip like this one. However you should check with your engineer first to make sure that this is acceptable. You may be better off constructing the floor joists per the engineering plans and damping the floors by using a 2nd layer of plywood with Green Glue in between or constructing a floating floor using the joist isolaters and utilizing the sound control carpet underlayment if you will be having carpet in the room(s).

39) Larry: My customer has a bathroom on a common wall with a bedroom. He wants to remove the sheetrock in the bedroom, insulate with fiberglass, then cover the wall with 3/4 plywood, then 1/2' drywall on that. Space is not an issue. Would a new 2x4 wall spaced 1' away from the existing wall, with insulation and 1/2' sheetrock be more sound canceling than his plan?

Trademark Soundproofing Reply: The new wall if fully decoupled from the first wall, will be more effective (if you have an open air space above the 2 walls you will need to soundproof the ceilings as well).

40) Richard S: I have a 3/4' subfloor with 1/2' insulation board and another 3/4' subfloor layer on the second floor. I will put a 12MM rubber underlayment on that and finish with a laminate floor. If I decouple the ceiling below this floor and do 2 layers of sheetrock with green glue will this be enough to stop the impact noise from above?

Trademark Soundproofing Reply: If you decouple with resilient sound clips that will be a great ceiling/floor combination and the impact noise should be dramatically reduced.

41) Jeff: We are turning our basement into an in-law suite. The basement had an existing drywall ceiling which we have already removed. We found existing R-19 fiberglass batt insulation in the ceiling cavity. Should we replace that with a different type of insulation? Or should we leave it and add additional insulation like the fiberglass panels or rockwool insulation? Or are just the R-19 batts enough insulation and instead I should spend more money on decoupling? Thanks!

Trademark Soundproofing Reply: R-19 is fine. Spend the extra effort and money on the decoupling and damping.

42) Mark Girgis: Hi,

I'm in the process of planning my kitchen reno project in a condo and have decided to tear down walls to add sound proofing to one of the walls and ceiling which are the common walls with the neighbor. Would like some thoughts on what I plan to do after hours of research online about methods.

1. Walls

The connecting wall with the neghboring condo is one on which kitchen cabinets and backspash tile will be applied. I cut a small opening to look inside to see what I am dealing with since I currently have noise transfer when cabinet doors are closing and voices.

I found that we have a standard wall, 5/8 inch drywall on each side connected directly to studs, and pink insulation in between. The cavity between the 2 sheets of drywal is 5 inches (approx) . My plan is to remove wall, add rock wool safe n sound, a sheet of 1lb MLV (1/8th) , and Certainteed 5/8 Silent Fx drywall. It's a small kitchen, very tight to fit stove and counter from wall to wall so I cannot afford to lose too much space which is why I will not add 2 layers of drywall. Since i only want to do this once :), I am contemplating putting a 2lb MLV which is 1/4 inch which I can still manage for space, but debating if the additional cost will add any value ( almost double the 1lb) especially since I will be mounting lower and upper cabinets on the wall as well as a tile backsplash on the portion between counter and upper cabinets. WOuld like to hear your thoughts.

2. Ceiling.

Similarly, I cut a hole in the ceiling to see what I was dealing with. Found 5/8 drywall mounted on resilient hat channel (looks like 5/8') which is mounted to wood furring strip (about 9/16th) which is lowering the ceiling from the studs a total of approx 1.2 inches. This looks to be the same across the entire condo ceiling which. I was surprised because I get a lot of impact noise from walking even though the decoupling is there. I am thinking the installation is short circuited in many areas. Again, my plan is to tackle this while I have the opportunity,

Will remove 5/8 drywall, fill space between floor and ceiling with Rock wool ( 2 layers), remove resilient channel, staple 1lb MLV, replace resilient channel with new ( or lower profile RC if possible since I am adding a 1/8inch layer of MLV) . Can't see that I can remove the wood furring strips because it seems to be overlapping with other rooms over ceiling. Lastly will put 5/8 silent fx drywall.

Putty pads and acoustical caulk will also be applied.

Is this overkill? What do you think ? :)

Thanks in advance for any help you can provide.

Mark

Trademark Soundproofing Reply: Hi. 1 lb MLV is fine for your application. Definitely not overkill on the ceiling and if you are having an impact noise issue there you should consider using resilient sound clips and hat channel for the ceiling if you can afford to lose an inch of space.

43) Mark G: Thanks for the response. I think I’m good for the wall.

I was looking into the clips today for the ceiling as an option. The ceiling will go too low if I put MLV, clips and new hat channel so I am thinking that I should remove the 1/2 inch wood furring strip which is really probably making the impact noise worse since it’s attached directly to studs ( correct me if I’m wrong). I was looking for a low profile clip, but The ones I’ve seen attach to the side of the joists which I feel is going to create a conduit for the impact noise. What can I expect to be he projection from joist to drywall with a standard clip ? Will have to add this to the 1/8 inch MLV to get the total distance that the ceiling will be lowered.

So the options if I remove 1/2 inch wood wood furring would be:

Option 1: rock wool, then MLV to joists then clips and hat channel and 5/8 silent fx. What would be the projection?

Option 2: rock wool with clips then 5/8 silent fx ( no MLV) Will I lose significant performance? What would be the projection?

Thanks in advance, much appreciated.

Mark

Trademark Soundproofing Reply: Hi Mark. Ceiling projection for clips and channel is an inch and 5/8. The commercial Whisper Clip is an inch and a half. The low profile clip is attached to the side of the joist however it works just as well as the others as the channel skims right below the joists and does not touch the joists. You would save about 5/8 of inch using those.

44) Seth H: I am planning to soundproof an open ceiling in an unfinished basement. In addition to decoupling the drywall from the joists with sound clips and hat channel, I want something in the cavity between the joists. To save money what do think about putting 40 oz/8 lb synthetic fiber carpet pad in there instead of insulation? It’s density would seem like an advantage.

Trademark Soundproofing Reply: It is to thin. You are better off with R-19 fiberglass.

45) Sebastian: Hello, I'm soundproofing a home theater room and I need some advice for insulating the ceiling. Above the theater room is the attic. I'm using RSIC clips + hat channel and 2 layers of 5/8'' drywall with Green Glue in between. For insulation, the current plan is to use a cellulose loose fill 30LB R-49 blow in. If the insulation is in contact with the drywall, would that negatively impact the decoupled ceiling?

Thanks in advance!

-Sebastian

Trademark Soundproofing Reply: That would not be a problem.

46) Marvin: Your guys' site has given me so much information! Can't wait to tackle this project and I'll definitely be using you guys for materials!

Quick question - renovating my upstairs office/media room which is directly over our master bedroom. I plan on ripping out the existing carpet and subfloor which will give me access to the inside of the master bedroom's ceiling cavity.

1 - Seal all voids/holes with acoustical sealant? put down insulation? is there much benefit to this?

2 - instead of going with another layer of plywood and GG for the subfloor, why not use MLV over the subfloor and as the underlayment to my vinyl plank flooring?

3 - any other recommendations are greatly appreciated! just don't think my wife will be too thrilled if I start ripping out the ceiling over our bed to decouple it.

thanks again!

Trademark Soundproofing Reply: Thank you Marvin.

1. Good idea. Every soundproofing project should begin with Insulation.

2. Green Glue will help with the damping somewhat, of the footfall and I wouldn't skip that. You can do the MLV on top of the 2nd subfloor.

3.Carpet will be much more effective if footfall is a concern.

47) Jake Mil: Hello! I’m planning on building a 14x14 room for streaming games in the back yard. It’s going to be very close to my neighbor’s house - their porch and sliding glass doors specifically - and I was wondering if it would be possible to do full soundproofing on the wall facing their house, but use only insulation on the rest? I don’t want to disturb them but I’m also not sure if full soundproofing is necessary. Thankyou!

Trademark Soundproofing Reply: For best results you would need to do full soundproofing otherwise the sound will flank thru the untreated walls/ceiling. Happy Gaming!

48) anthony richard: Hello TradeMark Soundproofing,

I love that your website that gives so much info and I am super excited to get my project done. I have a single family home in the bay area and plan to turn my basement into an in law. Height is about 8 ft and is bare bones at the moment. I do plan to insulate it with fiberglass, decouple the ceiling with hat channel and clips, place MLV 1/8 inch to prevent impact as well as ambient noise and double dry wall with green glue in between. how much STC rating will I get out of this? is this overkill and how much height will i be losing?

I am also planning to do the same to my walls in my bedrooms with the clips and double dry wall and MLV. I do have a bedroom that will share a common wall with a bathroom. will this be good enough to prevent toilet flushing noise/pipes/water running or do i need to build another wall to not hear any sound from the bathroom?

last final question for the floors. can i place MLV to absorb sound or is there a cheaper alternative?

thank you

Trademark Soundproofing Reply:

Hi Anthony. Thank you. That is not overkill and is good sound control practice. Your STC should be in the high 50's You will lose about 2.25 inches from the height of the room when using clips channels and 2 layers of drywall. Be sure not to use recessed lights. If you like the look of them see our surface mounted LED Lights. The walls in the Room is also good, make sure there is insulaton in the bays of the pipes as well and you can wrap the pipes with MLV before closing the wall. Important that you soundproof the ceiling of your room as well if there is an open attic above as the sound will jump the wall and come in thru the ceiling. Cheaper alternative for the floor is carpet with thick padding.

49) Josh E: Here's a new one for you: I'm building a shipping container house, 4 containers on one level. Acoustics are worse than anticipated. What's the best way to soundproof a wall between containers in this situation? I don't have or need studs, I can attach directly to the corrugated steel sidewall quite easily including glue-only options.

50) Peter W: Hi, and thank you for your very informative website and great products. I have a contractor rebuilding a music studio room that got stripped down to the rafters and studs after some water damage. Perfect opportunity to do the sound isolation right. He will be ordering from your site. My question is about your ceiling instructions. We plan to do insulation, then whisperclips and hat channels, then two layers of drywall with Green Glue between. For the insulation, do you mean standard flexible 8' or so rolls? Or do you mean one layer of the rigid 2' Owens-Corning batting you sell? The rafters are 9' deep and 12' on center, with x-shaped cross bracing between them. Anything else we should be doing? Thank you.

Trademark Soundproofing Reply: Your welcome. You should use the fluffy insulation. In your case R-30 or R38 fiberglass insulation.

51) Debbie: For a basement guest room (currently an unfinished space), would we get better soundproofing by installing a drop ceiling, or RSIC clips + hat channel + 2 layers of sheetrock with GG in between? I'm nervous to do sheetrock because of possible upstairs water leaks or needing plumbing access in the ceiling. If drop ceiling gives good results, that would be easier and cheaper. If we do drop ceiling, is recessed lighting still a bad idea? How about a ceiling cassette for a ductless mini-split A/C system? Thank you!

Trademark Soundproofing Reply: Drop ceilings do not so much at all in regards to soundproofing. The first option is way way better.

52) David Wasserman: Looking to convert unfinished attic to a home theater. Trying to figure out the best approach to reduce sound transmission (especially LFE with 4 large subwoofers) to the second floor where the bedrooms exist. Currently I have 2x10s for the joists, fiberglass insulation in-between, and an OSB subfloor.

Would it be worth it to pull up the existing subfloor to replace fiberglass insulation with Rockwool AFB and add joist isolators before reinstalling the subfloor? If I install Rockwool between the joists, how thick should this be (one or two layers of 4' AFB)?

Or would I be better off just installing green glue and a second layer of OSB for the floor (which I would do even if I pulled up the existing OSB)?

Thank you in advance.

Trademark Soundproofing Reply: For the insulation alone it would not be worth to pull up the floor. However for the Joist isolators it is worth it. @ layers of 4' AFB plus 2 layers of subflooring with Green Glue in between over the joist isolators is the way to go.

53) Scott Matson: I have built a double wall but I nailed the top plate of the wall to the ceiling joists. There is a clip to decouple that joint that I have become aware of, but I have to rebuild the wall to use the clips.

The ceiling will be hung on clips with hat channel, two layers 5/8 and green glue.

My question is, how much sound transmission will I get from the walls being tied into the ceiling? I can correct the construction but it will be at significant cost. I just don't know how much of a difference it will make to add the clips to decouple the wall frame from the ceiling joists.

Asking for your advice.

Scott

Trademark Soundproofing Reply: Hi Scott. Sorry for the late reply. If the ceiling is being hung with Sound Isolation Clips and Channel you do not need to redo the current construction you have in place.

54) Jon S: Hi, I live in an apartment building underneath a family of 8 that constantly hosts more guests. They are a very active household. I have been hearing impact noise of them running and heavy walking back and forth. and furniture scraping. I've convinced them to get coasters on the chairs, so only hear that occasionally. they added luxury vinyl tiles on their living room and hallway floor with a thin underlayment (wish it would have been thicker.) the running and stomping does sound a drop muffled from what it use to be. but it is still very irritating at times. The management might approve opening the ceiling and adding insulation, clips, channel, double Rockwall with GG. But the building is very old and I am concerned there might be asbestos. what do you recommend ? would adding GG and a 5/8 muffle the impact sound pressure a little, if so by how much ?

Trademark Soundproofing Reply:

I would only do it if you can remove the ceiling add insulation with sound isolation clips and channels etc. the impact sound is the biggest concern and just adding another layer when there may not even be insulation will not be worth the effort.

55) Peter Madsen: Am building a music room/recording studio and we are planning on using RSIC clips w/hat channel plus 2 sheets 5/8' drywall. By my calculations, this will result in 2 7/8' between face of studs and surface of drywall. For lightswitches/outlet receptacles, how do we 'extend' those out to be flush w/the finished wall? All the tutorials I could find on the website showed outlets being attached to studs as if sheathing were to be attached directly to studs as well. Any tips are greatly appreciated. Thanks

Trademark Soundproofing Reply: They can be installed 'Further Out' when attaching them to the stud

. I am not familiar with the use of EPDM as it applies to soundproofing. In general it would depend on the weight. I would suggest that at least for the ceiling you should consider swapping out the EPDM for mass loaded vinyl. I would also simplfy your ceiling construction by eliminating the 2x3 grid system which will not add much as you will get the extra air space and proper decoupling with the

. I am not familiar with the use of EPDM as it applies to soundproofing. In general it would depend on the weight. I would suggest that at least for the ceiling you should consider swapping out the EPDM for mass loaded vinyl. I would also simplfy your ceiling construction by eliminating the 2x3 grid system which will not add much as you will get the extra air space and proper decoupling with the